The hot-dip galvanizing of galvanized cable ladder tray is to make the zinc liquid flow from the surface of the steel plate to produce an alloy layer, thus combining both the substrate and the coating. Hot-dip galvanizing has the advantages of uniform coating, strong adhesion, and a service life of more than 20 years. The cold galvanizing of galvanized cable tray is galvanized, and its own corrosion resistance is much worse than that of hot galvanizing. The price is also relatively cheaper.

The difference between the finished galvanized products: Hot-dip galvanizing is not as delicate and bright as cold-dip galvanizing, but the thickness of the zinc layer is dozens of times that of cold-dip galvanizing. The corrosion resistance is also dozens of times higher than that of electro-galvanizing. Stainless Steel On Stainless Steel

Selection and design of galvanized metal cable tray

Galvanized metal cable trays of strong and weak lines should be laid in separate slots, strong and weak power in the splitter box crossover shall be separated by a metal separation plate, strong and weak wires shall not be in direct contact with the line slot. The various wiring in the floor trunking is only allowed in the sub-box outlet joints. In the construction and installation of the floor cable trunking, all the trunking pipes are required to be connected to a reliable grounding as a whole. The following galvanized metal cable trunking selection design.

1. Determine the environmental conditions environmental conditions are generally three: corrosive environment, normal environment, special environment.

2. Determine the direction according to most cable direction, in the indoor can be along, column, beam, floor, in the outdoor as far as possible along the process pipeline.

3. Select the cable containment according to the cable load and cable trough installation at the environment, based on the load curve of the cable duct to determine the type and specification and the spacing of the column, the length of the bracket arm, the level of the cable bridge, the length of the column, etc.

4. According to the cable direction and the environment of the installation to determine the way to fix the cable tray; suspension, upright, wall-side type, etc.

Original Source: https://www.heshenggr.com/news/hot-dip-galvanizing-and-cold-dip-galvanizing-technology-for-galvanized-ladder-cable-tray/

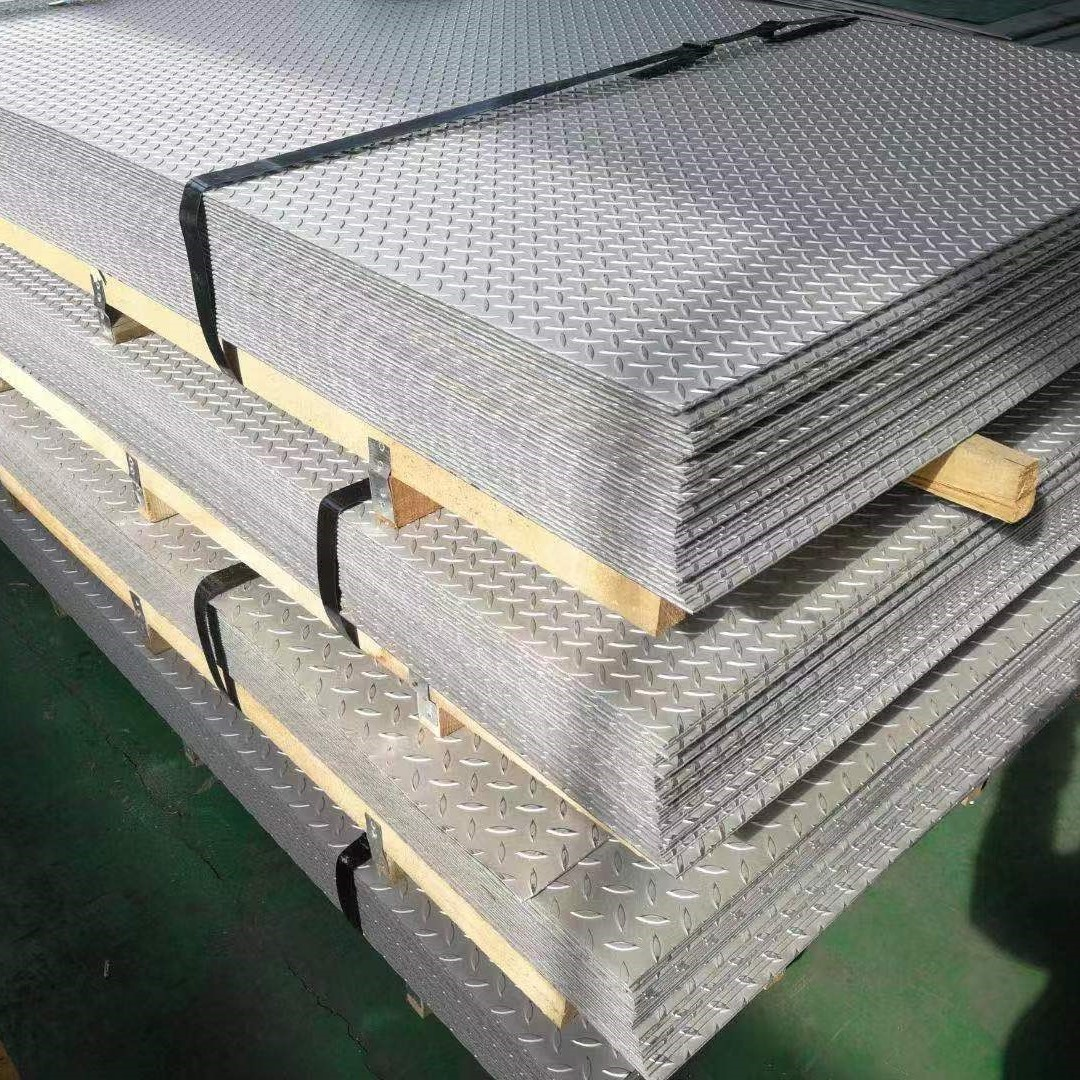

Galvanised Sheet Specification Media Contact Company Name: Hesheng Group Co., Ltd. Email: Send Email Phone: 0086-591-87500579 Address:28th Floor Yuanhong Building, Gulou District City: Fuzhou Country: China Website: https://www.heshenggr.com/